Definition of an On-Spot Loading Facility

An on-spot system refers to a filling station for railway tank cars that is equipped with a top filling system and impressive filling point loading performance. The railcars are filled in a similar way to an assembly line process, also known as the cycle process.

In the middle of the On-spot system, the filling tube is located on a hydraulically movable filling tube sledge. The railcars are positioned in front of the system by a locomotive. Using a railcar pulling system or a remote-controlled shunting vehicle, the first tank car is placed precisely under the filling point.

The filling pipe, controlled from a control point in the control room located directly on the track, is moved and inserted into the railcar dome. The railcar is then filled efficiently.

After filling is complete, the next railcar is positioned using the railcar pulling system or shunting vehicle (ROBOT), and this process is repeated until the entire railcar compound is filled.

Folding stairs in front of and behind the filling point are used to open and close the domes. The measurement, which requires calibration, takes place either via meters or via track scales directly at the respective filling point.

On-spot systems are divided into through track systems and dead end track systems. However, this distinction is particularly relevant in the delivery process of the railcars. For an on-spot system, the track length is designed to be twice the length the railcar compound.

The centerpiece of a Railcar On-Spot Loading-Facility –

Our Filling tube system

Robust, high quality, more successful than ever!

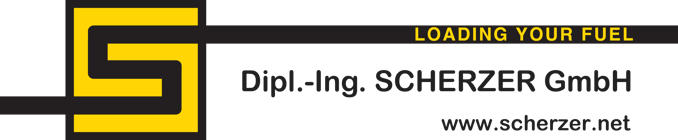

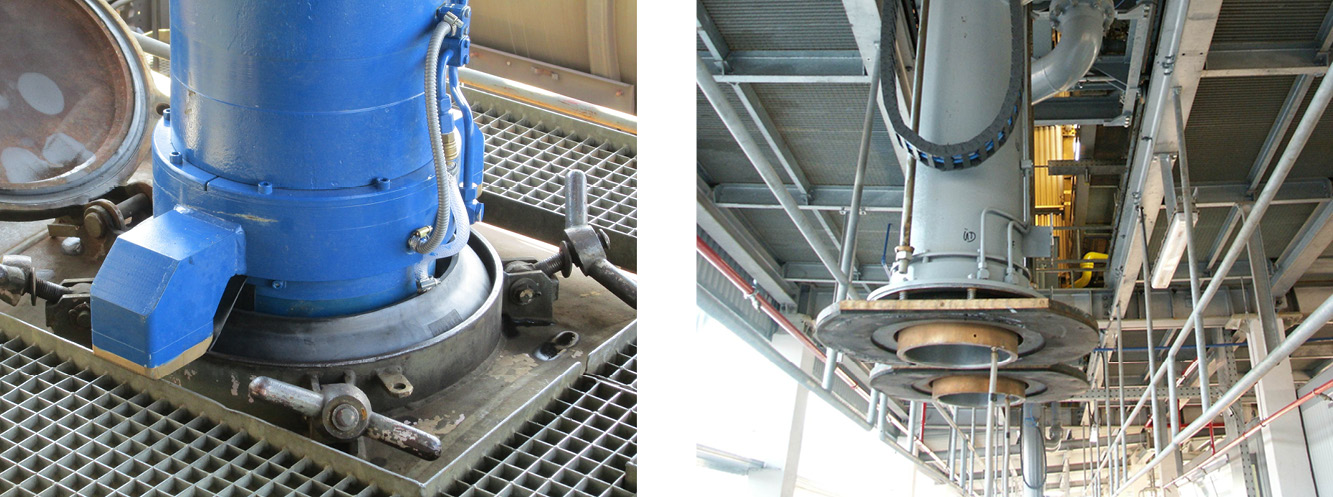

The central element of every SCHERZER loading and unloading system is without a doubt our SCHERZER filling tube technology, which was specially developed for individual customer needs. Through the use of robust machine technology, equipped with all devices for smooth and sustainable use, the SCHERZER filling pipe has successfully proven itself in over 200 systems, some of them for over 40 years.

With a hydraulic remote control, the pipe can be positioned effortlessly and precisely. The resilient mounting of the sealing plate between the filling pipe and the tank car dome enables problem-free replacement. The compensator allows flexible deflection of the protective tube, while inflating the sealing bellows ensures automatic centering of the lower filling tube. The gas is returned via a separate, high-quality telescopic tube with multiple seals – a proven system. Since 1988 we have delivered and installed more than 200 filling pipes with gas recirculation technology; in total we have already manufactured over 350 filling pipes!

The Filling Tube System

Flammable liquids are loaded into railcars using the filling tube system with the on-spot principle. The products reach the filling pipe system via various product lines and corresponding product collectors. Loading can be carried out on each track using a filling tube system, although additional systems can be retrofitted if necessary. After each loading, the filling system is completely emptied.

The filling tube system consists of:

- Filling tube sledge

- Filling tube

- Swivel joints

- Hydraulic unit

- Pneumatic unit

- Optional: Ground monitoring

You can find a clear summary in our brochures under downloads.

Find out more about our individual areas of rail car handling systems here

Filling tube system Single- and Serial loading Bottom loading Unloading